This is an attempt to put all the components together. I chose the front section with the two double slips. Here's how it looks on Anyrail:

It's getting interesting ...

I added a stripboard for the two 1N4001 diodes required for each output of the Lenz LS150. I think each stripboard will carry six sets of two diodes, so each stripboard will be dedicated to one single LS150. Here are two designs; I have not decided yet which one I will go with.

The stripboards are fairly cheap and not easy to cut, so it might make sense to keep the board as one piece and use the space for labeling and securing to the control panel.

For reference, here's the board I bought at MicroCenter: https://www.microcenter.com/product/505440/velleman-eurocard-full-line-fr4

Mine is reference ECL1/2, but it basically the same.

Sunday, December 15, 2019

Sunday, December 8, 2019

Switch - Part 3 - DCC command of switch motor

I finally got around the DCC control of a switch motor. I use the following components:

I chose the solution with the LS150 module because it needs a separate power supply to control the switch motors. Considering the number of switches I have, it might have been too much power taken from the main tracks to power the switches. The only downside I can see is that the Tortoise will relax at the end of throw as it is designed to be used as a stall device and the LS150 cannot keep the power on all the time.

I followed the LS150 instruction manual and the wiring diagram is fairly easy:

And here's what it looks like in real life:

A couple of details regarding the configuration of the LS150:

- You cannot control the pulse duration from the ECoS; it needs to be configured with the LS150 itself - see below

- In the video, I set the pulse duration to 5 sec; I believe it is a bit too long but it cannot harm the switch motor since it expects to be powered all the time

- The english version of the instruction manual can be found here.

Monday, December 2, 2019

Train detection and identification

To ensure automation, train detection is required. I'm using ESU ECoS Detector: http://www.esu.eu/en/products/digital-control/ecosdetector/ecosdetector/

I wanted to run a quick prototype to make sure I understand how it works before going on the actual layout.

The English manual is easily found on the Internet and the wiring is pretty straight forward: one of the tracks is isolated and gets its feed from the ECoSDetector instead of directly from the ECoS Command Station. The ECoSDetector gets a direct feed from the ECoS Command Station.

It is very important to follow 0 is black and is direct to the track, whereas B is read and goes through the ECoSDetector.

Now, it is easy to link the ECoSDetector to the track diagram on the ECoS Command Station by using the icon circled in red below:

When everything is wired up and correctly configured, here is what happens:

The track in red shows that this section is occupied!

This is all great, but we actually don't know which engine is on that occupied section. Enters RailCom. Decoders equipped with the RailCom protocol can communicate back to the digital station.

I need to insert a RailCom box on the track diagram on the ECoS Command Station by using the icon circled in red below:

So, same as above, but now with RailCom:

We actually see the name of the engine on the track diagram. Unfortunately, ECoSDetector 50094 has only 4 RailCom inputs out of the 16 inputs. However, ESU offers the ECoSDetector RC 50098 that provides only RailCom inputs, but one module has only 4 inputs: http://www.esu.eu/en/products/digital-control/ecosdetector/ecosdetector-rc/

I wanted to run a quick prototype to make sure I understand how it works before going on the actual layout.

Train detection

The English manual is easily found on the Internet and the wiring is pretty straight forward: one of the tracks is isolated and gets its feed from the ECoSDetector instead of directly from the ECoS Command Station. The ECoSDetector gets a direct feed from the ECoS Command Station.

It is very important to follow 0 is black and is direct to the track, whereas B is read and goes through the ECoSDetector.

Now, it is easy to link the ECoSDetector to the track diagram on the ECoS Command Station by using the icon circled in red below:

When everything is wired up and correctly configured, here is what happens:

The track in red shows that this section is occupied!

Train identification

This is all great, but we actually don't know which engine is on that occupied section. Enters RailCom. Decoders equipped with the RailCom protocol can communicate back to the digital station.

I need to insert a RailCom box on the track diagram on the ECoS Command Station by using the icon circled in red below:

So, same as above, but now with RailCom:

We actually see the name of the engine on the track diagram. Unfortunately, ECoSDetector 50094 has only 4 RailCom inputs out of the 16 inputs. However, ESU offers the ECoSDetector RC 50098 that provides only RailCom inputs, but one module has only 4 inputs: http://www.esu.eu/en/products/digital-control/ecosdetector/ecosdetector-rc/

Friday, November 29, 2019

ECoS Command Station

I bought the ESU ECoS Command Station a while back, but I never posted here my first steps with it.

The first thing is to connect the ECoS Command Station to the wifi for two main purposes:

Connection to Wifi

The first thing is to connect the ECoS Command Station to the wifi for two main purposes:

- Update firmware

- Upload custom images for locomotives

The ECoS Command Station has an ethernet port, so I bought a Wifi bridge here.

I don't remember how to configure it, but it was very easy; I probably had to connect it directly to a laptop for the first setup.

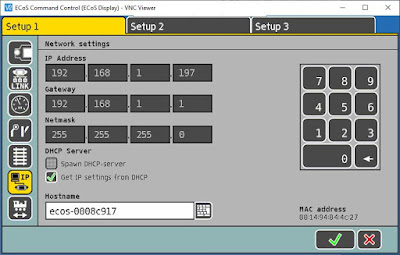

You can then check the IP address of the ECoS Command Station on the network:

ECoS Command Station portal

I can now access the portal of the ECoS Command Station from a web browser on the network. This is the URL: http://192.168.1.197/en/index.html

Custom images for locomotives

There are plenty of user-generated images for locomotives beyond those provided by default by ESU. They can be found and downloaded here: http://www.esu.eu/en/downloads/loco-pictures/

Once you save the image on your computer, you can upload it to the ECoS Command Station from its portal.

You will need to restart the ECoS Command Station before you can see it on the station itself.

Labels:

ecos

Wiring ... completed

All tracks are finally soldered and positioned!

The next step is ... more wiring ... All the "little" wires are underneath the plywood and need to be connected to the main bus feeder:

The next step is ... more wiring ... All the "little" wires are underneath the plywood and need to be connected to the main bus feeder:

Saturday, November 9, 2019

Wiring ... continued

All tracks and switches have been soldered!

I've tried a slightly different approach to soldering switch, especially for the frog - green wire. I actually broke a frog wire of a double slip and it is a very expensive mistake. For now on, instead of having to drill right underneath the frog, I leave more of the bare wire from Peco that runs under the sleeper and I drill right next to the sleeper:

I've tried a slightly different approach to soldering switch, especially for the frog - green wire. I actually broke a frog wire of a double slip and it is a very expensive mistake. For now on, instead of having to drill right underneath the frog, I leave more of the bare wire from Peco that runs under the sleeper and I drill right next to the sleeper:

Sunday, October 20, 2019

Wiring

Now that the track-bed is done and the tracks positioned on top of the track-bed, it is time for wiring. There are three activities here:

This is for a simple Peco Electrofrog Switch.

- Wiring switches

- Wiring tracks

- Drilling through the plywood for those wires

Wiring basics

I use solid color cables gauge 22 to wire switches and tracks. I also use heat shrink tubes to protect the solder between the small wire from the switch and the wire cable.

I bought the wires and the tubes at Micro Center:

- Wires: https://www.microcenter.com/product/404659/elenco-22-gauge-solid-hook-up-wire-25-foot-6-color-kit

- Heat shrink tubes: https://www.microcenter.com/product/391392/nte-electronics-multi-color-assorted-4-inch-heat-shrink-tubing

Wiring switches

I went through this step in detail in this post here. I'm only putting pictures.

This is for a Peco Double Slip Switch (SL-U8363 Code 83 Unifrog #6).

This is for a simple Peco Electrofrog Switch.

This is quite time consuming:

Wiring tracks

This is very straight forward. I used either a fiberglass scratch brush (https://smile.amazon.com/gp/product/B002RMCFZM) or a small file to prepare the bottom of the track for soldering.

Then, I use liquid electrical tape to protect the solder - https://smile.amazon.com/gp/product/B0000AXNOD

Drilling through the plywood for those wires

Once all wires have been soldered to switches and tracks, I put them back in place and drill through the plywood. For wires, I use a 5/32 bit for the wires, and a 1/2 bit for the switch motor.

It is time consuming and will probably take a few weeks to complete.

Saturday, September 28, 2019

Track-bed is done!

All track-beds have been positioned and glued down:

The next steps are to solder all the wires to the tracks and switches, make holes in the platform for all the wires and the moving points of the switches, then glue the tracks!

The next steps are to solder all the wires to the tracks and switches, make holes in the platform for all the wires and the moving points of the switches, then glue the tracks!

Labels:

track

Friday, September 20, 2019

Track-bed

Since I made the outline of all the tracks, I removed them and I can start installing the track-bed foam.

Outline

Track-bed

I am using the Woodland Scenics products:- Track-Bed strips: https://woodlandscenics.woodlandscenics.com/show/item/ST1461

- Foam Tack glue: https://woodlandscenics.woodlandscenics.com/show/item/ST1444

I'm pretty sure any white glue would do, but I decided to go for peace of mind. The process is fairly easy: put some glue on the plywood, lay the foam, and put some weight for 10 minutes to ensure full contact:

The straight sections are very easy and fast to install:

The curves are a bit tricker. Here's my process. I cut the foam in half along the long side - there is a pre-cut that I follow with a hobby knife. I made some blue marks on a piece of plywood to serve as a gauge: the center mark is the center on the track, the two other blue marks on the side are for the tracks, and the sides of the piece of wood are the bottom of the track-bed.

I then trace the center of the tracks with the blue Sharpie and put pins. These pins will hold the position of the curved track-bed:

The curved sections are actually quite time consuming. Should be done soon ...

Labels:

track

Subscribe to:

Posts (Atom)